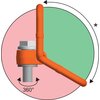

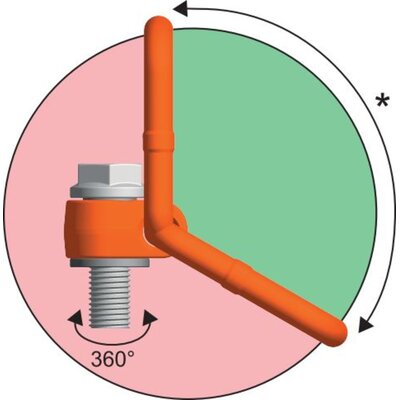

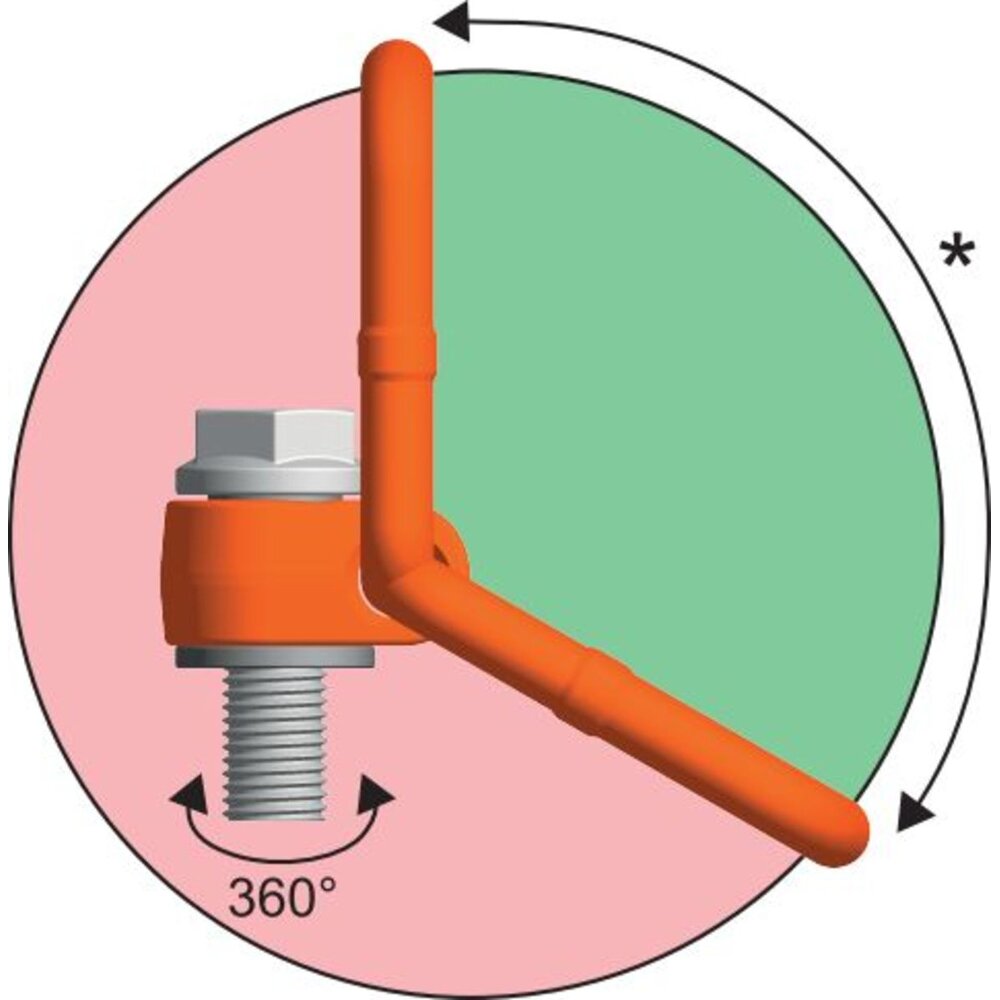

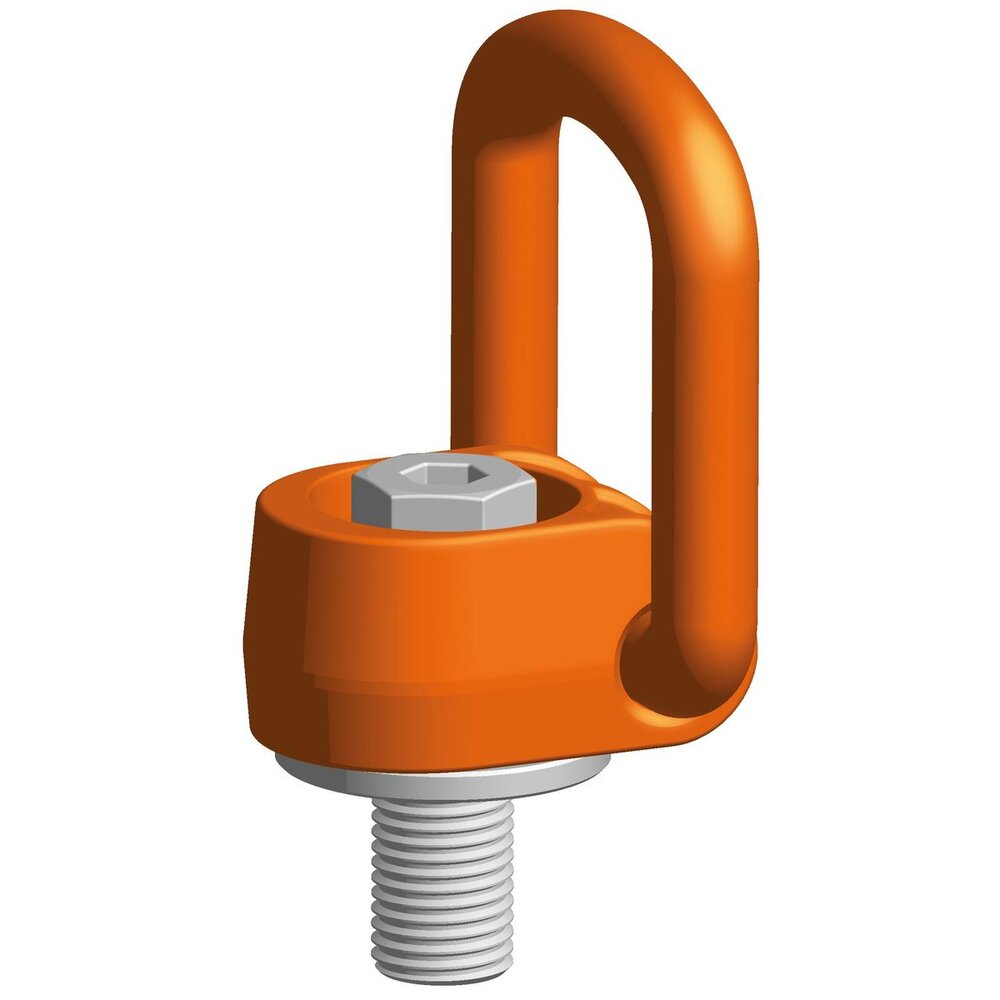

360° rotatable lifting point. The load ring is loadable in a range of 130° and can be positioned at any required angle due to its replaceable and patented spring. Likewise interchangeable is the hexagon-special screw from grade 10.9 material, which is secured against loss. The screw is 100% crack detection tested as well as covered with a chromate VI-free protection against corrosion.

pewag winner profilift alpha is able to withstand a 4-fold safety against break in all directions. It is avaliable with metric or UNC-thread, whereas the lifting points with metric thread is also obtainable with customized thread lengths.

Permissible usage

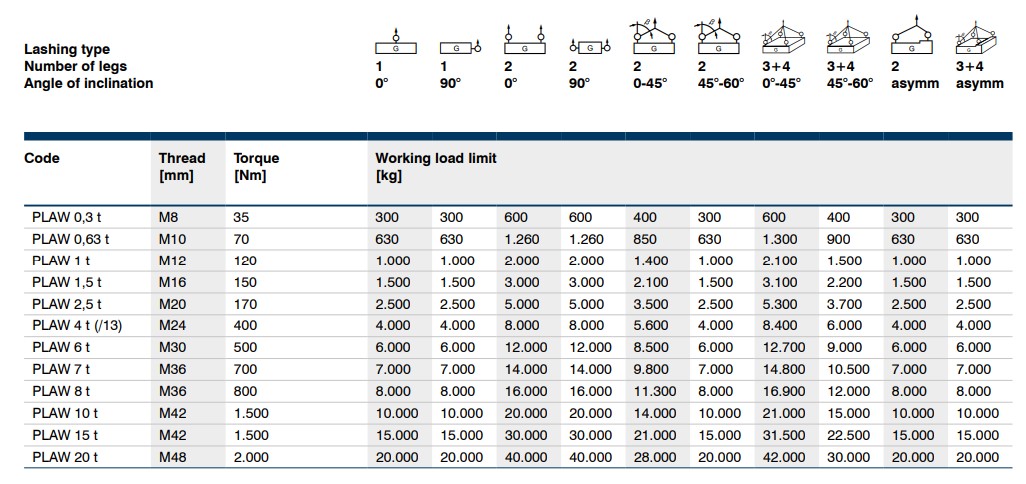

Load capacity acc. to the inspection certificate respectively table of WLL in the mentioned directions of pull (see picture 1).

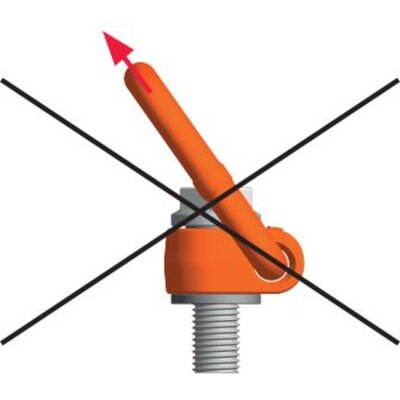

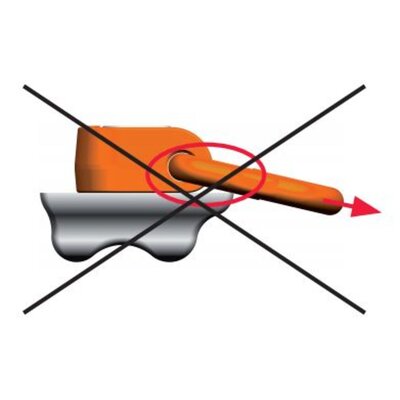

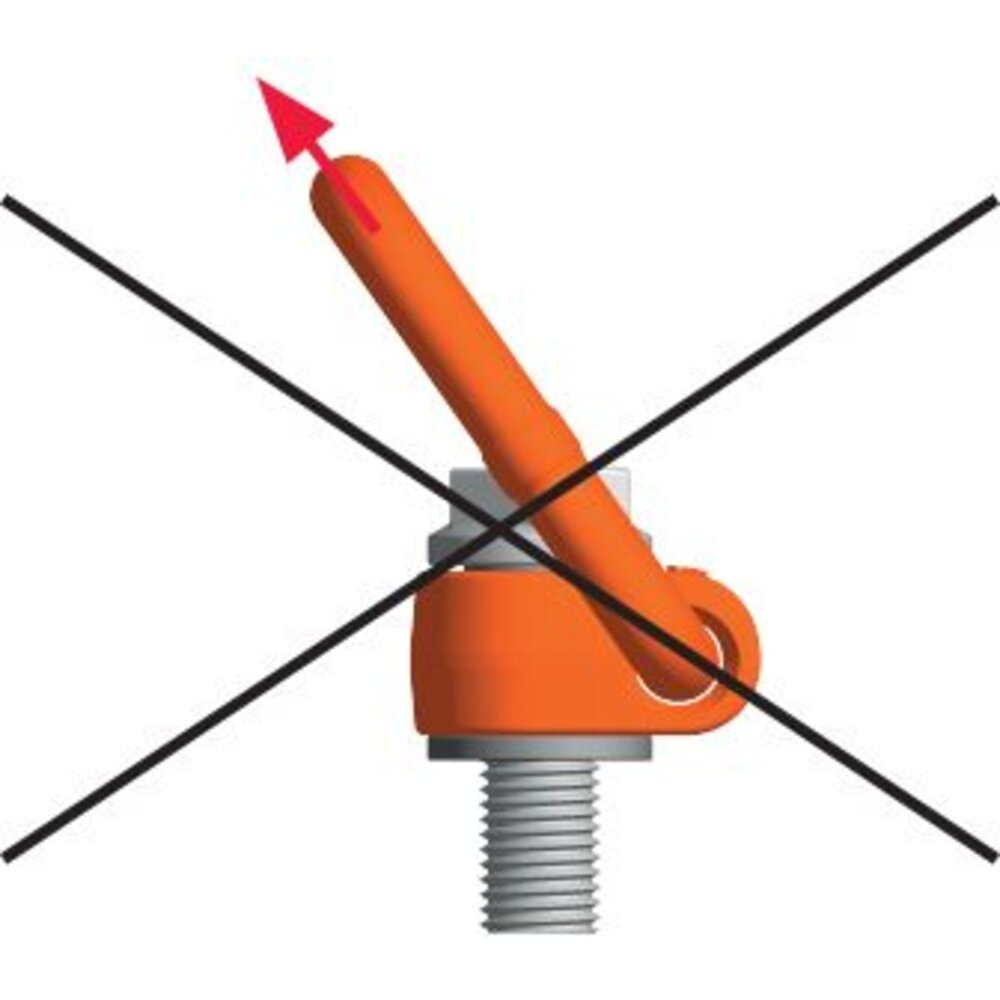

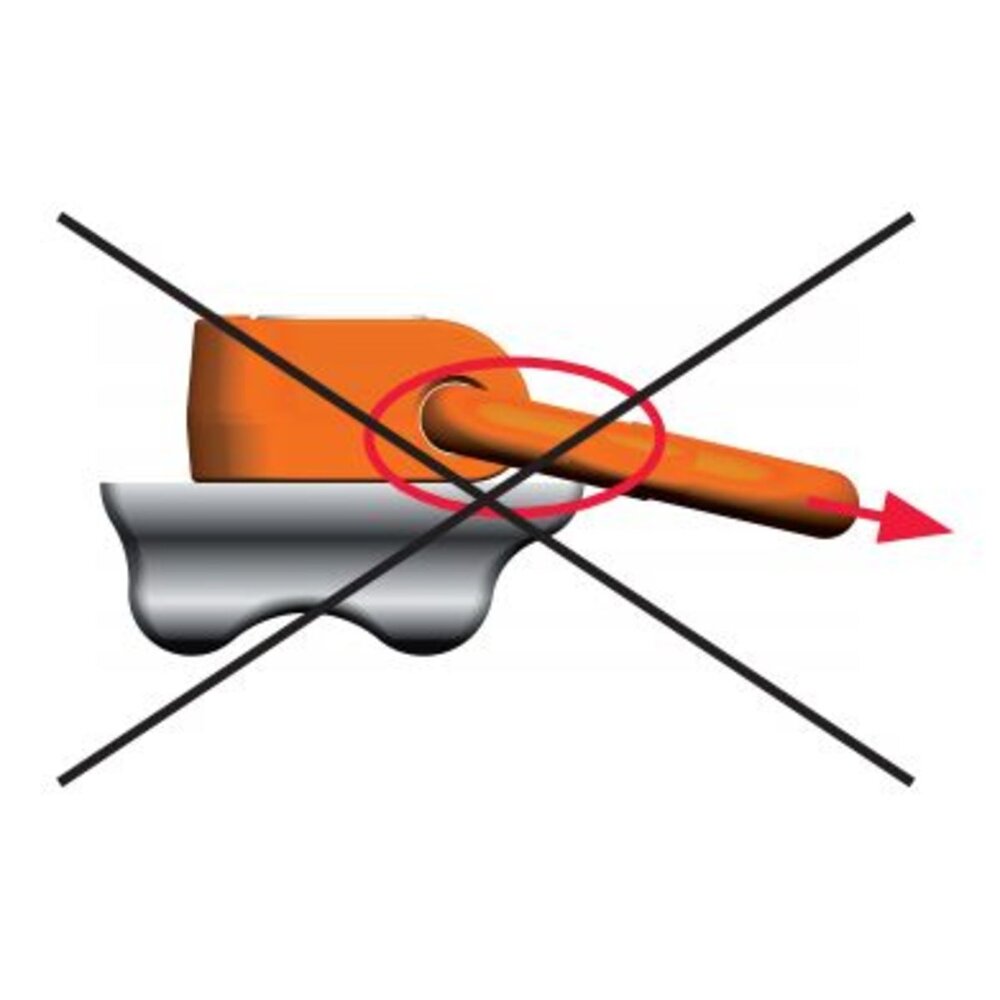

Non permissible usage

Make sure when choosing the assembly that improper load can not arise e.g. if:

- The direction of pull is obstructed

- Direction of pull is not in the foreseen area (see picture 2)

- Load ring rests against edges or loads (picture 3)

The load ring must be placed in the direction of pull before loading - do not turn under load. For more details please have a look into our user manual.

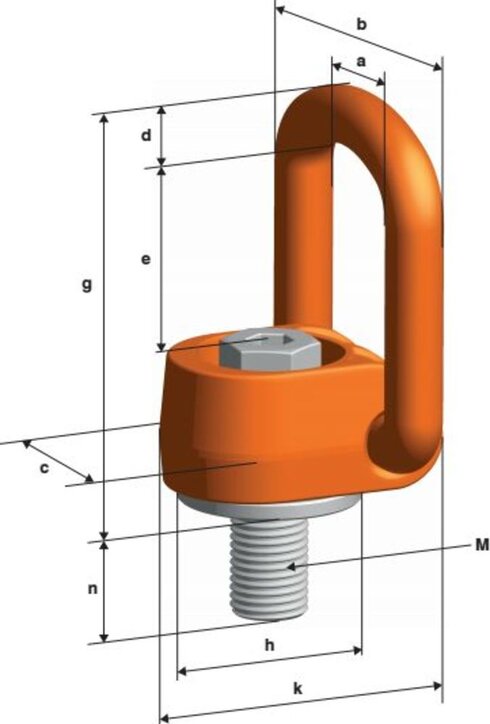

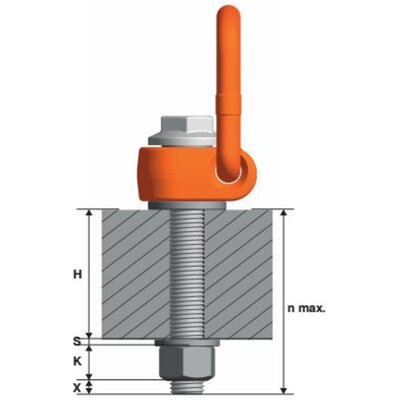

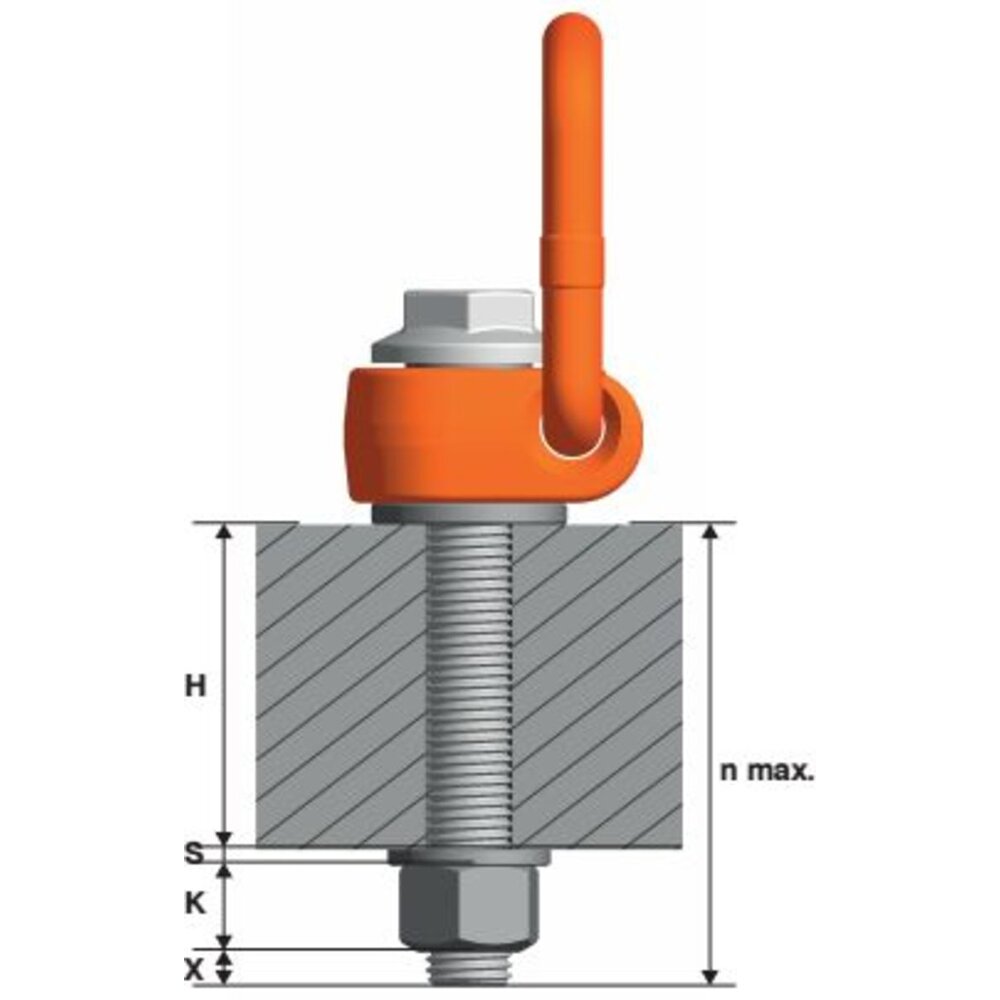

To calculate the necessary thread length (L):

L = H + S +K + X

H = Material height

S = Thickness of the washer

K = Height of the nut (depending on the thread size of the screw)

X = Excess length of the screw (twofold pitch of the screw)

L max. = n max.

pewag provides, along with the standard and maximum thread lengths, specially customised thread lengths. Supplied customised and maxium thread lengths include a washer and a crack-tested, corrosion-proofed screw nut.

- Material: Alloy steel

- Marking: According to standard, CE-marked, WLL, thread size and an individual serial number.

- Finish: Painted.

-

Standard:

EN 1677-1

except grade/WLL

- Safety factor: 4:1